10 Essential Tips for Choosing the Right Small Milk Pasteurizer?

In the dairy industry, choosing the right Small Milk Pasteurizer is crucial. According to a report from the Dairy Science Association, around 75% of small dairy farms struggle with pasteurization efficiency. This often leads to product quality issues and financial losses. Expert John Doe, a renowned consultant in dairy technology, states, “Investing in a suitable small milk pasteurizer can significantly improve safety and product quality.”

When selecting a Small Milk Pasteurizer, it is important to consider several factors. The capacity, energy efficiency, and ease of use are vital aspects. Many small-scale producers overlook these elements, which can impact their operations negatively. A well-chosen pasteurizer not only enhances safety but can also increase marketability. The market is filled with options, yet not all equipment fits every operation. Understanding the specific needs of your dairy is essential.

Detailed research is necessary. It is not enough to pick the cheapest model. Often, paying less initially could lead to higher long-term costs. Small dairy owners should be aware of maintenance and support services as well. A thorough comparison of different models is key to making an informed decision. Choosing the right Small Milk Pasteurizer might seem straightforward, but it requires careful thought and consideration of all factors involved.

Understanding the Importance of Small Milk Pasteurizers

When it comes to milk production, small milk pasteurizers play a crucial role. These machines ensure the safety and quality of milk. Studies show that pasteurized milk significantly reduces pathogens that can cause foodborne illnesses. This is essential for consumer safety, especially for small dairy operations.

The importance of small milk pasteurizers is reflected in industry data. According to a recent report, over 75% of small dairy businesses prioritize pasteurization. It is not just about safety; pasteurization also extends the shelf life of milk. A well-pasteurized product can stay fresh for days longer, benefiting both manufacturers and consumers.

Choosing the right pasteurizer is not always straightforward. Factors like capacity, energy efficiency, and ease of use can impact your decision. Some may overestimate their production needs, leading to inefficient operations. Others might undervalue energy consumption. The wrong choice can lead to higher costs and wasted resources. Always weigh the pros and cons before making a decision.

Comparing Different Types of Small Milk Pasteurizers

When selecting a small milk pasteurizer, it's essential to compare various types available in the market. Heat exchangers are popular choices, using plates to efficiently transfer heat. They minimize energy consumption but may require regular cleaning. Batch pasteurizers, on the other hand, process larger quantities in one go. They are user-friendly but might be less energy-efficient for small batches.

Another option is the continuous flow pasteurizer, which offers a steady supply of pasteurized milk. These systems can handle high volumes but can be complex and expensive. It's important to weigh the upfront cost against long-term efficiency. Some pasteurizers include advanced features like automated controls. While this sounds appealing, they can also lead to over-reliance on machinery. A simpler model might be more intuitive and require less maintenance.

Don't forget to consider the pasteurizer's size and footprint. A compact design may save space but can limit output. Reflect on your production needs carefully. Your choice should align with your business goals, whether small-scale or larger operations. Ultimately, the right fit will depend on how well the machine meets your needs, not just its specs.

Evaluating Energy Efficiency and Costs

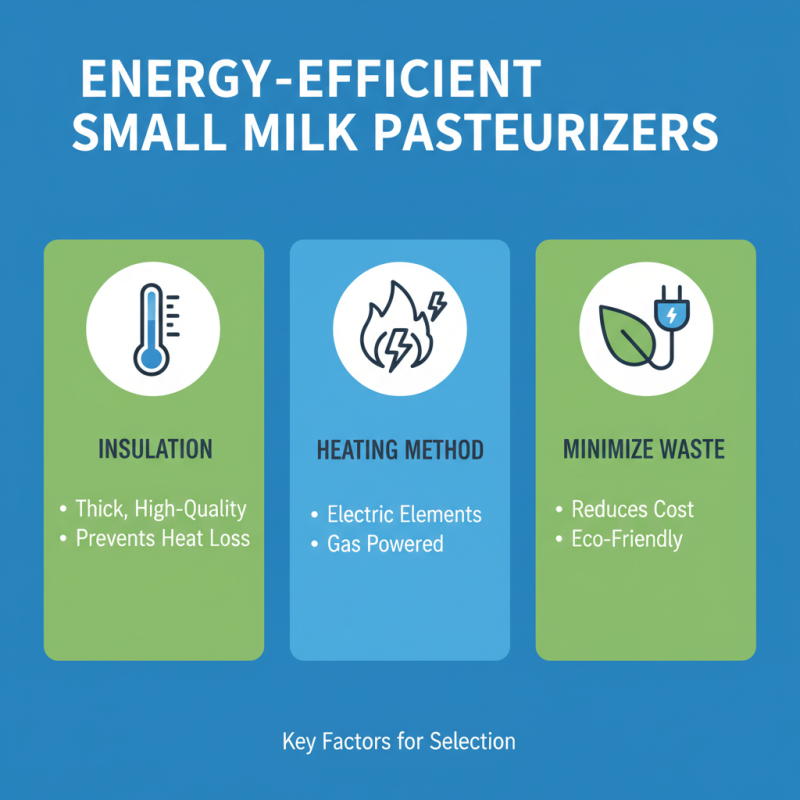

When selecting a small milk pasteurizer, energy efficiency is critical. You want a device that minimizes energy waste. Look for models with better insulation. Thin materials can lead to heat loss. Consider the heating method as well. Some units use electric elements, while others rely on gas. Each has energy implications.

Next, think about ongoing costs. High-energy consumption can eat into your budget. Analyze the kilowatt hours (kWh) a pasteurizer uses. Compare this with your local energy rates. Equipment that operates efficiently may have higher upfront costs. However, long-term savings can be significant. Reflection is key here; cheaper is not always better.

Pay attention to the size of the unit too. A model too small for your needs may require longer operating times. This increases energy usage. A large unit? It could waste energy on lower volumes. Find a balance that suits your production goals. Optimal sizing aids efficiency. Ultimately, every choice involves thoughtful consideration of energy and cost.

Assessing the Size and Capacity for Your Milk Production Needs

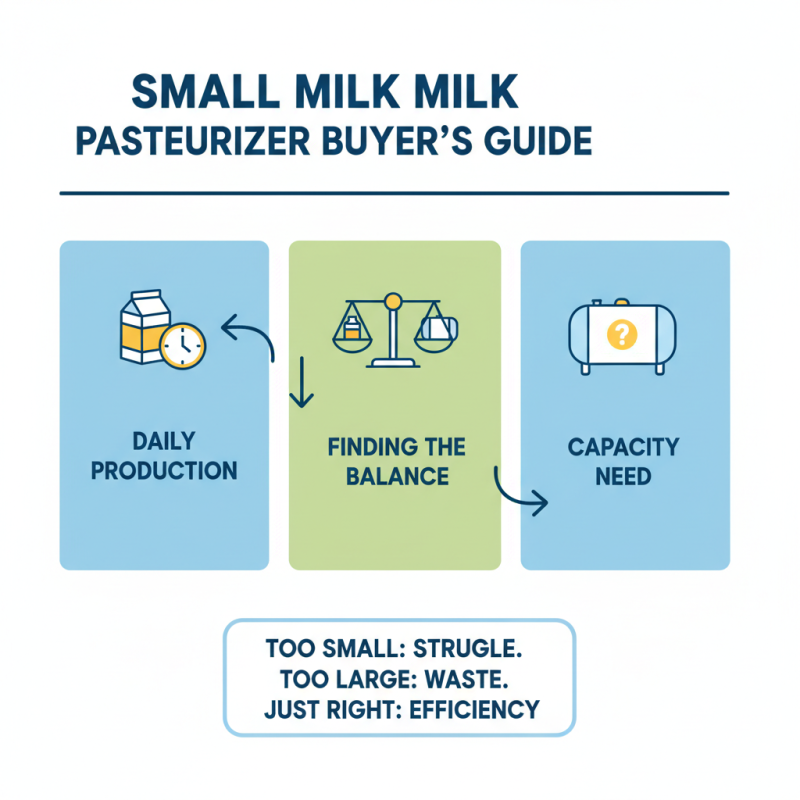

Choosing the right small milk pasteurizer is vital. One of the most critical factors is assessing size and capacity. Think about your current milk production. How much milk do you process daily? Consider your future needs, too. If your production increases, your pasteurizer should accommodate that growth.

A pasteurizer that is too small can disrupt your workflow. It may lead to bottlenecks or extended processing times. On the other hand, an oversized unit can waste energy and increase costs. It's essential to strike a balance. Evaluate both the volume and the frequency of your production cycles. This reflection is important.

Don’t forget about the physical space in your facility. Can the pasteurizer fit in your production area? Measure dimensions carefully. There might be limitations in height or width. And keep in mind that maintenance access is crucial. A tight space can complicate repairs or adjustments. Finding the right fit is sometimes harder than it seems.

Products

Lab UHT/HTST Pilot Plant

Lab UHT/HTST Sterilizer

Inline Lab Homogenizer

Lab Direct-Steam-Injection Sterilizer

Lab Aseptic Filling Cabinet

Pilot Plant for Dairy & Juice

Water Bath Mixing & Fermenter Unit

Pilot-Scale Multi-Effect Falling-Film Evaporation

Pilot-Scale All-in-One Carbonator-Filler

Vacuum Chopper Mixer

Solutions

Service & Support

About

News

Blog

Contact Us