10 Best Pilot Plant Equipment for Efficient Production Processes?

In the realm of industrial production, the importance of Pilot Plant Equipment cannot be overstated. As John Smith, a renowned expert in chemical engineering, puts it, "The right pilot plant equipment can make or break a project." Choosing the best equipment is essential for achieving efficient production processes. Each component plays a crucial role in scaling up from lab to full production.

Pilot plants serve as a testing ground for new processes and formulations. This is where innovative ideas meet practical application. However, navigating the complexities of pilot plant equipment can be challenging. Many factors come into play. For instance, the choice of reactors and mixers must align with the specific product requirements.

Investment in high-quality equipment is vital, but it's often underappreciated. Companies may cut corners, leading to inefficiencies later. Reflecting on past experiences shows that the selection process is often rushed. This oversight can result in setbacks. The goal is not just speed but sustainable, efficient production. Let’s explore the ten best pilot plant equipment options that can enhance production and drive innovation.

Overview of Pilot Plant Equipment and Its Importance in Production

Pilot plants serve as a crucial bridge between research and full-scale production. They allow manufacturers to test processes and equipment on a smaller scale. This helps identify potential issues early, minimizing risks in the final production phase. The flexibility of pilot plant equipment enables adjustments based on experimental outcomes.

Key equipment includes mixers, reactors, and separators. Each plays a significant role in optimizing production processes. For example, a well-designed reactor can enhance reaction efficiency. However, sometimes these systems require extensive troubleshooting. Unexpected results can arise, highlighting the need for continuous improvement.

Investing in diverse pilot plant equipment is essential. This allows for a variety of production scenarios. Engineers and scientists must collaborate closely. They should be open to feedback. A culture of learning from failures can lead to better processes and higher product quality. Embracing imperfections enhances innovation in production strategies.

Key Attributes of Effective Pilot Plant Equipment

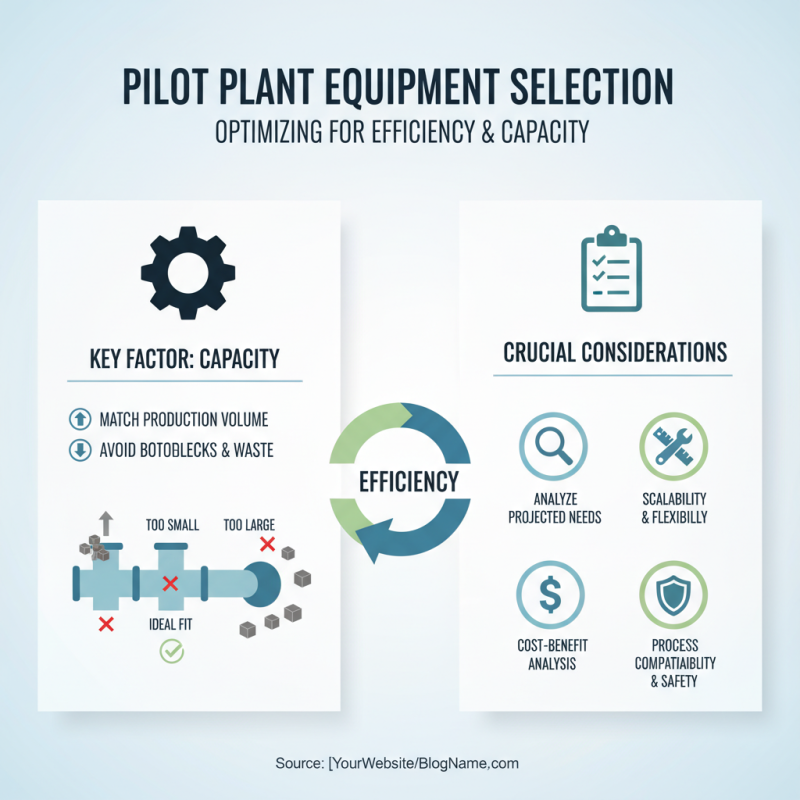

When selecting pilot plant equipment, certain key attributes significantly influence production efficiency. Flexibility stands out. Equipment must adapt to different formulations and scales. According to a recent industry report, 70% of companies emphasize the importance of versatile systems that can quickly switch between various processes.

Another crucial attribute is scalability. Equipment must be capable of transitioning from pilot scale to full production. A study from an engineering firm indicated that over 60% of failed projects were due to inadequate scalability. This highlights the importance of understanding processing capacities and limitations. Companies need to invest in tools that can grow with their demands.

Precision and automation also play vital roles. Modern pilot plants require accurate data collection for better decision-making. A report from the International Journal of Chemical Engineering noted that automated systems improved process consistency by 40%. In contrast, manual operations often lead to errors. This gap illustrates the need for reflection on current practices. Investing in reliable, automated equipment is essential for driving efficiency.

Top 10 Pilot Plant Equipment for Streamlined Production Processes

In the world of pilot plants, efficiency is crucial. Streamlined production processes depend on the right equipment. Recent studies show that optimizing these systems can enhance productivity by over 30%. Investing in effective technologies directly impacts overall yield and operational costs.

One key piece of pilot plant equipment is the multifunctional reactor. This unit performs various tasks, from mixing to heating. Data indicates that using advanced reactors can cut down processing times and improve consistency. However, operators must remain vigilant about maintenance. Neglecting regular checks can lead to costly downtime.

Another essential tool is the automated control system. Automation helps reduce human error, ensuring precise measurements. Reports show automation can boost accuracy by up to 25%. Yet, as technology evolves, training the workforce becomes a challenge. Continuous education is vital for maximizing equipment potential. If not addressed, skill gaps can hinder the benefits of automation.

10 Best Pilot Plant Equipment for Efficient Production Processes

| Equipment |

Function |

Material |

Capacity |

Efficiency Rating |

| Reactor |

Chemical reactions |

Stainless Steel |

1000 Liters |

High |

| Heat Exchanger |

Heat transfer |

Copper |

500 Liters/hr |

Medium |

| Filtration System |

Solid-liquid separation |

Plastic |

200 Liters/hr |

High |

| Mixing Tank |

Mixing solutions |

Stainless Steel |

500 Liters |

Medium |

| Pumping System |

Fluid transport |

Cast Iron |

1000 Liters/hr |

High |

| Drying Oven |

Drying materials |

Metal |

10 kg |

Medium |

| Storage Tank |

Storing products |

Polyethylene |

2000 Liters |

High |

| Cooling Tower |

Cooling fluids |

Aluminum |

1500 Liters/hr |

High |

| Control System |

Process automation |

Electronic |

N/A |

Very High |

Future Trends in Pilot Plant Equipment Design and Functionality

The landscape of pilot plant equipment design is evolving rapidly. Industry reports indicate a shift toward automation and smart technologies. According to a recent report from the International Society for Pharmaceutical Engineering, 65% of pilot plants are now integrating advanced manufacturing technologies to enhance operational efficiency. This trend is largely driven by the need for faster product development cycles.

Automation plays a critical role in reducing human error and improving consistency. With the rise of IoT, connectivity between equipment is becoming crucial. Real-time data analytics is another significant aspect. However, challenges remain. Many facilities struggle with the integration of these advanced systems. Training staff to adapt can be difficult, and downtime during upgrades may affect production.

Sustainability is a growing focus. Recent surveys indicate that over 50% of pilot plant managers prioritize eco-friendly processes. This includes energy-efficient machinery and waste reduction initiatives. Yet, transitioning to sustainable practices often involves upfront costs that deter some businesses. Balancing innovation with practicality is a constant struggle in the industry. The future of pilot plants will undoubtedly demand a more strategic approach to equipment design.

10 Best Pilot Plant Equipment for Efficient Production Processes

Products

Lab UHT/HTST Pilot Plant

Lab UHT/HTST Sterilizer

Inline Lab Homogenizer

Lab Direct-Steam-Injection Sterilizer

Lab Aseptic Filling Cabinet

Pilot Plant for Dairy & Juice

Water Bath Mixing & Fermenter Unit

Pilot-Scale Multi-Effect Falling-Film Evaporation

Pilot-Scale All-in-One Carbonator-Filler

Vacuum Chopper Mixer

Solutions

Service & Support

About

News

Blog

Contact Us