What is Automated Quality Control?

Automated Quality Control (AQC) refers to the use of Programmable Logic Controllers (PLC) and sensors to monitor, record, and regulate key process parameters—such as temperature, pressure, flow rate, and product concentration—in real time.

Through closed-loop feedback control, the system adjusts operations to stay within predefined tolerances, ensuring stable product quality and repeatable batch outcomes.

This technology reduces human error, improves production traceability, and enhances compliance with HACCP, GMP, and ISO standards.

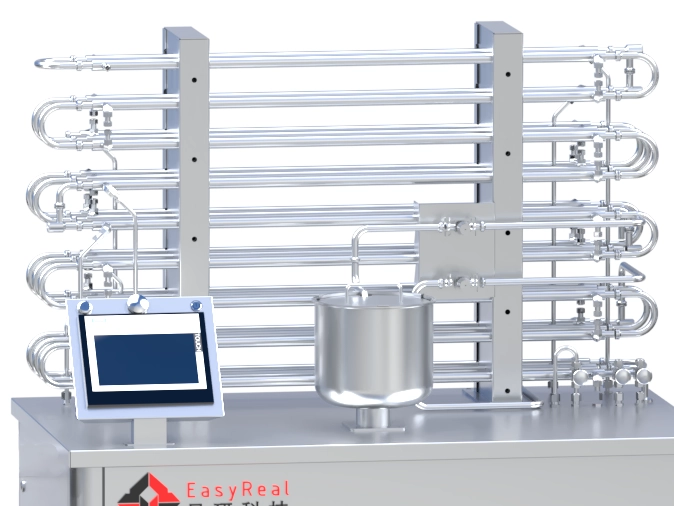

EasyReal LC-Based AQC System

Shanghai EasyReal Machinery Co., Ltd. integrates PLC-based quality control systems into all major process units—such as UHT, mixing, homogenizing, filling, and cleaning modules—providing comprehensive digital supervision of the entire line.

Our control platform supports multilingual interfaces and is compatible with Siemens, Mitsubishi, Schneider, and other industrial PLC brands, suitable for both pilot and industrial-scale operations.